Your shopping bag is empty

Pinnacle Cutting Nozzles - ANME: Versatile Cutting Solutions for Professionals

Pinnacle Cutting Nozzles - ANME offer versatile cutting solutions designed to meet the demands of professionals. Crafted with precision and durability in mind, these nozzles excel in a variety of cutting applications. Constructed from solid copper alloy, they are built to last and provide reliable performance. The user-friendly design ensures easy installation and operation, making them suitable for both professionals and DIY enthusiasts. With ANME Cutting Nozzles, you can achieve precise and accurate cuts while maintaining low pressure for efficient cutting.

Key Features:

- Exceptional Durability: Crafted from solid copper alloy, our ANME nozzles are built to withstand the rigors of cutting applications.

- Ease of Use: Designed for easy installation and operation, these nozzles are suitable for professionals and DIYers.

- Versatile Performance: ANME Cutting Nozzles excel in various cutting applications, offering precision and efficiency.

Product Specifications:

- Product Type: Cutting Nozzles - ANME

- Material: Copper Alloy

- Gas Mix: Oxygen and Acetylene (Confined to the Nozzle)

- Pressure: Low Pressure

How It Works:

ANME Cutting Nozzles efficiently mix Oxygen and Acetylene gases within the nozzle while maintaining low pressure. This process ensures precise and accurate cuts. The copper alloy construction enhances durability and reliability.

Available Sizes:

- Cutting Nozzle ANME 1/32 0.8mm (3 - 6 mm)

- Cutting Nozzle ANME 3/64 1.2mm (6 - 12 mm)

- Cutting Nozzle ANME 1/16 1.6mm (12 - 75 mm)

- Cutting Nozzle ANME 5/64 2.0mm (75 - 100 mm)

- Cutting Nozzle ANME 3/32 2.4mm (100 - 150 mm)

- Cutting Nozzle ANME 1/8 3.2mm (150 - )

What Is the Difference Between an ANME and PNME Cutting Nozzles?

ANME Cutting Nozzles are designed for versatile cutting applications, providing precise and efficient cuts by mixing Oxygen and Acetylene gases within the nozzle while maintaining low pressure. In contrast, PNME nozzles have a different design and are primarily used for gouging and heating.

What Are the 2 Main Types of Cutting Nozzles?

The two main types of cutting nozzles are ANME and PNME. ANME nozzles are suitable for versatile cutting applications, while PNME nozzles are primarily used for gouging and heating.

What Is the Difference Between PNM and ANME Nozzles?

PNM and ANME nozzles have distinct designs and purposes. PNM nozzles are primarily used for gouging and heating, while ANME nozzles are suitable for versatile cutting applications, mixing Oxygen and Acetylene gases while maintaining low pressure.

What Is a Cutting Nozzle?

A cutting nozzle is a specialized tool used in oxy-fuel cutting processes to mix gases and direct them to achieve precise and efficient cutting in various materials.

Related products

5kg 0.9mm Pinnacle Flux Core Gasless MIG Welding Wire - E71T-11

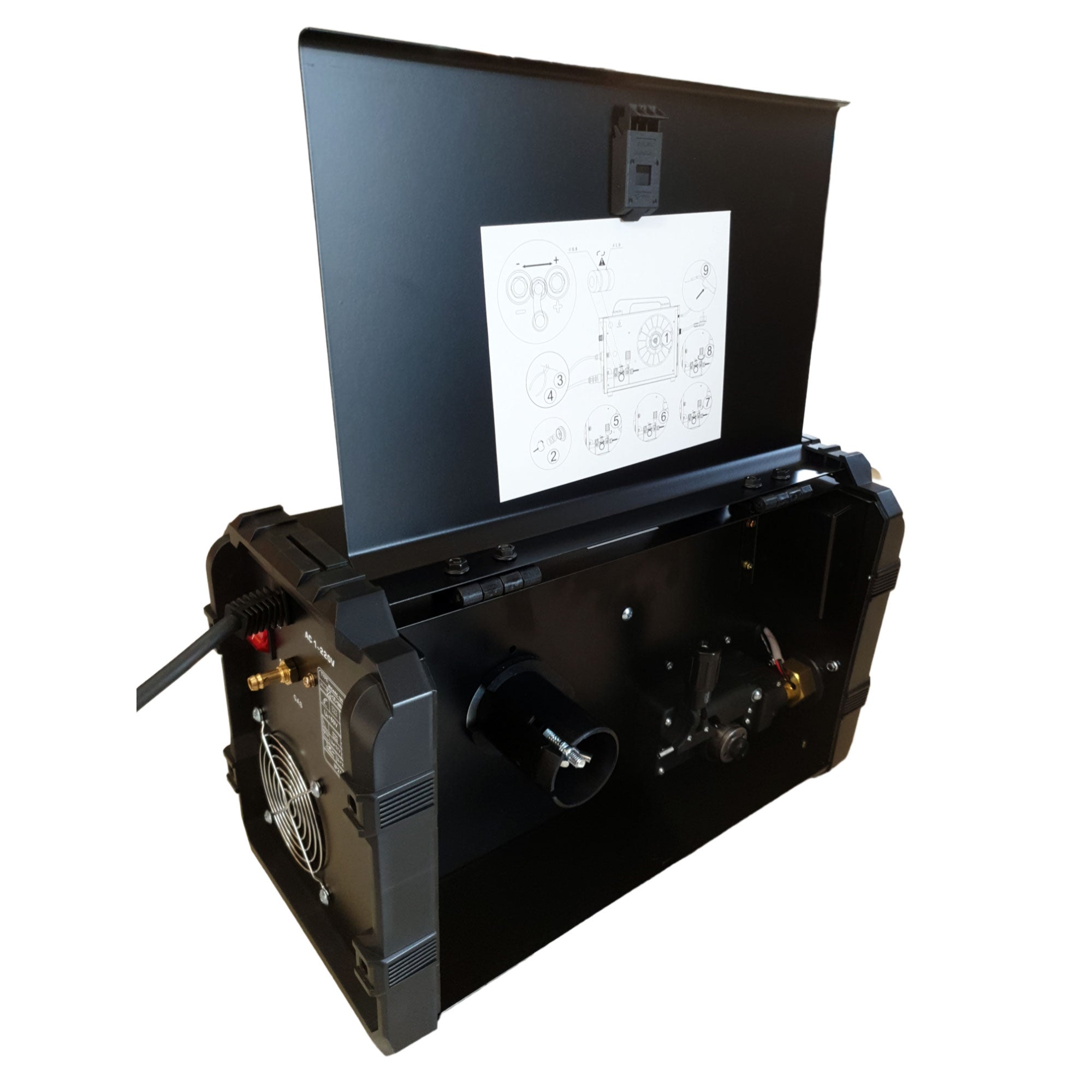

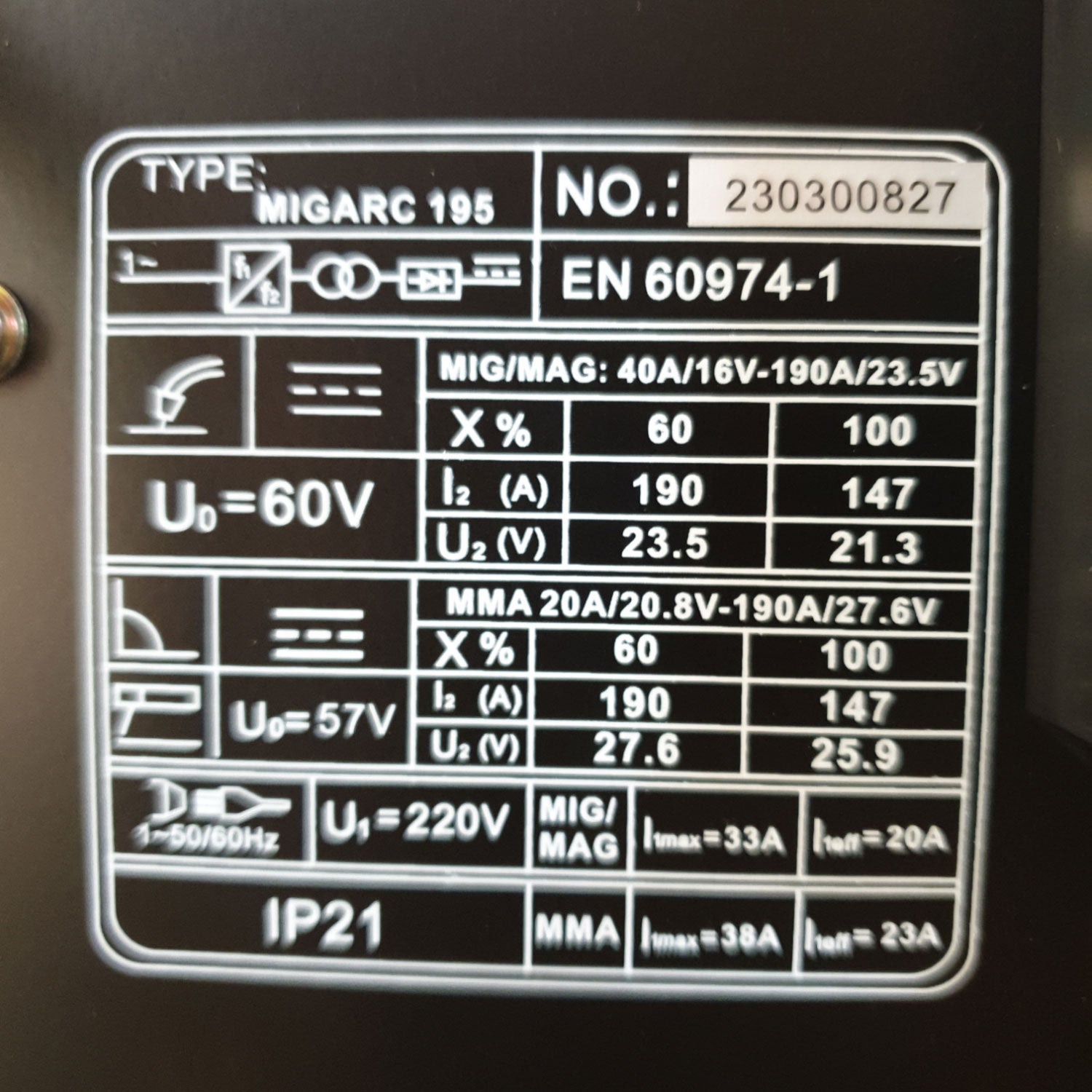

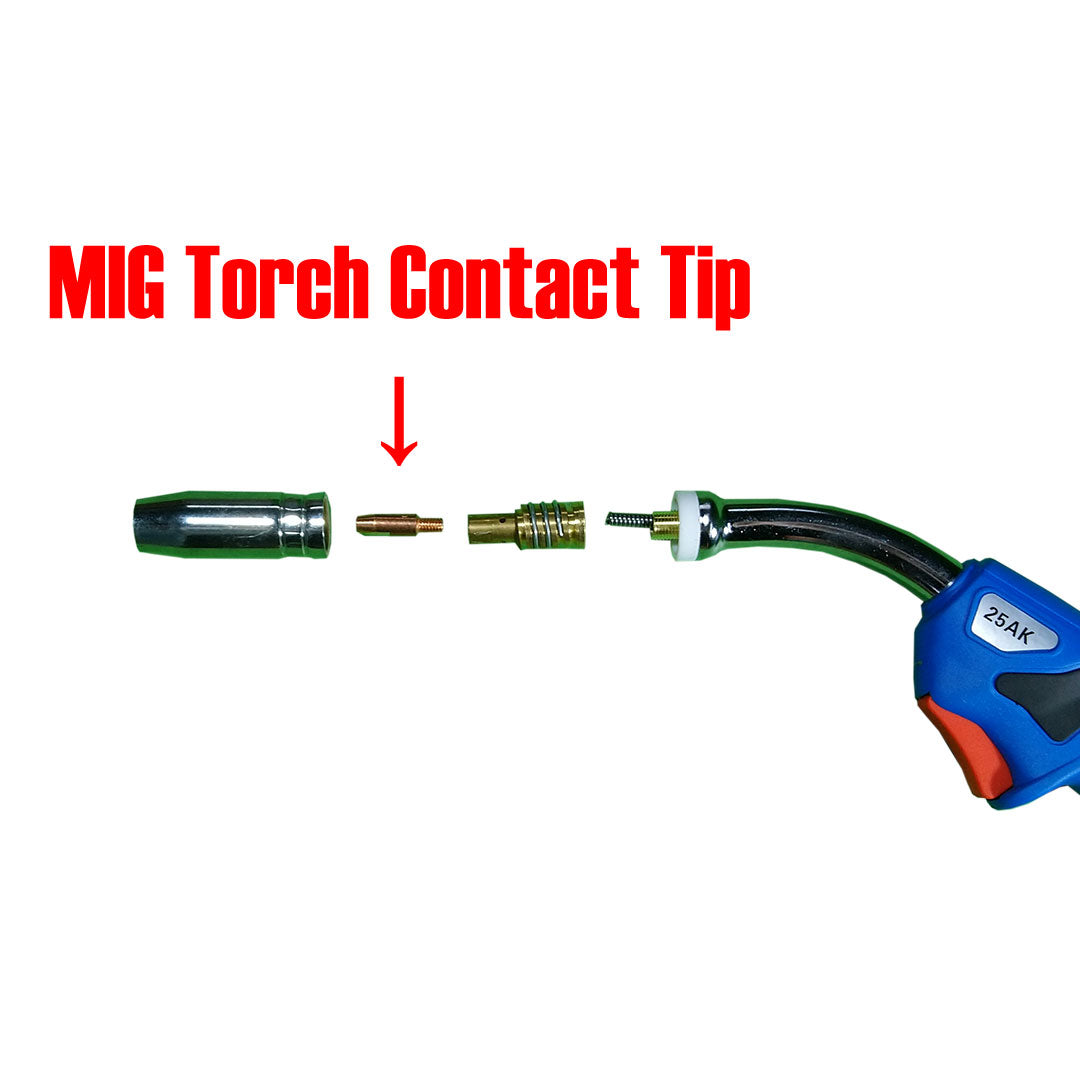

New Pinnacle MIGARC 195 Multi-Process MIG Welding Machine

10% Off Combo Kits

-

MIG Welding Machine Combo

Pinnacle Welding MIGARC 195 Gasless MIG Welding Machine Combo

-

R 4,899.00R 4,399.00

-

-

MIG Welding Machine Combo

Pinnacle Welding MIGARC 200 Digital Gasless Welding Combo Kit

-

R 6,895.00R 6,099.00

-

-

ARC Welding Machine Combo

Pinnacle Welding GENE SP 22 ARC Welding Machine Combo Kit

-

R 2,249.00R 2,024.00

-

-

ARC Welding Machine COmbo

Pinnacle Welding IntruARC 161 ARC Welding Machine Combo Kit

-

R 1,999.00R 1,799.00

-

-

MIG Welding Machine Combo

Pinnacle Welding MIGARC 195 Gas MIG Welding Machine Combo

-

R 4,499.00R 4,399.00

-